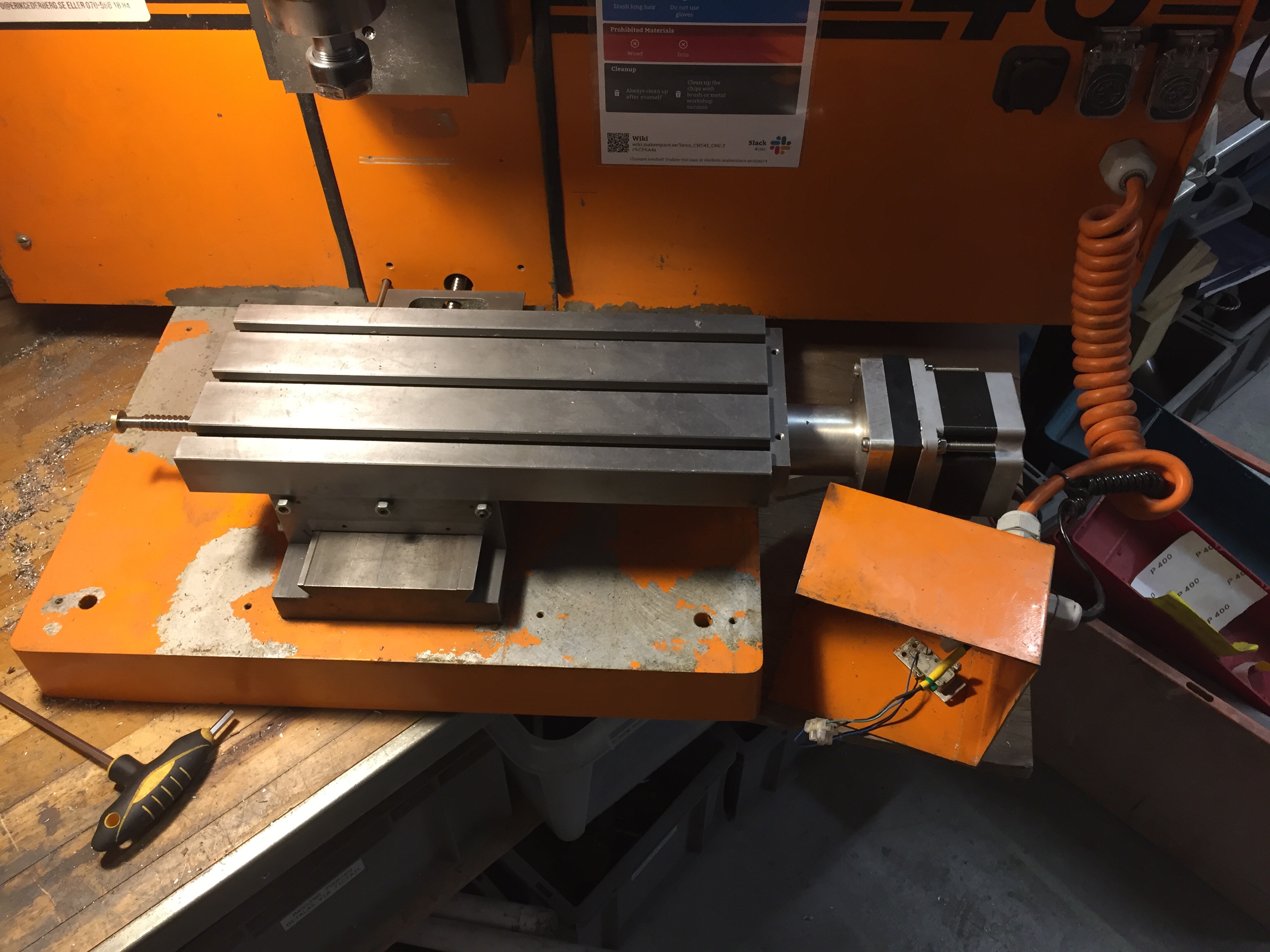

So first attempt att making a real part today, and on top of that I wanted to try the new superglue+masking tape method. Many have spread the word about this method, but NYC CNC do it best, as usual:

The problem is that none of the products they mention can be bought in Sweden, and even their links to Amazon are getting stale. So I tried TESA Premium Classic masking tape and Loctite Power Flex Gel. I gave the glue a few minutes to harden properly below.

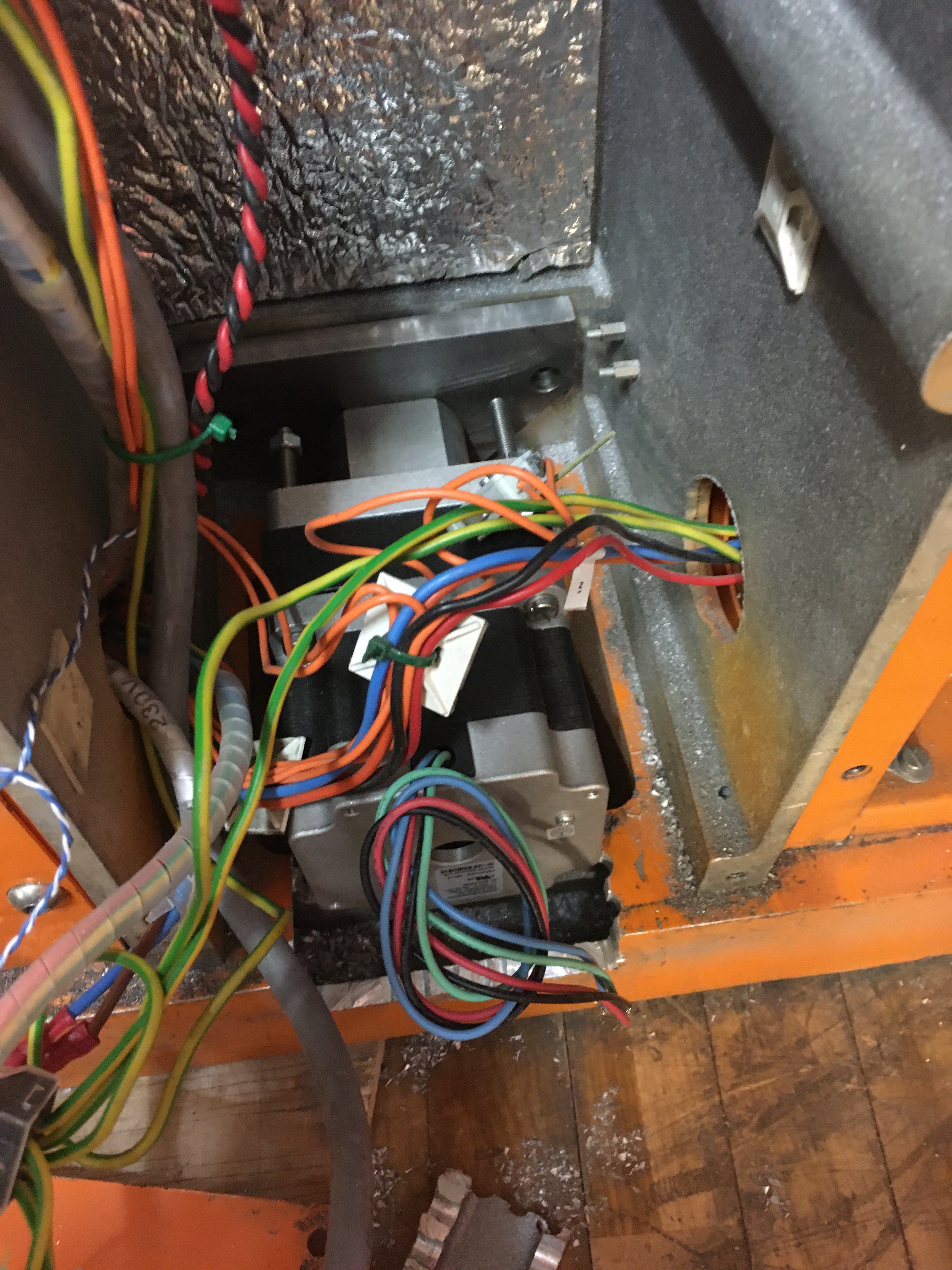

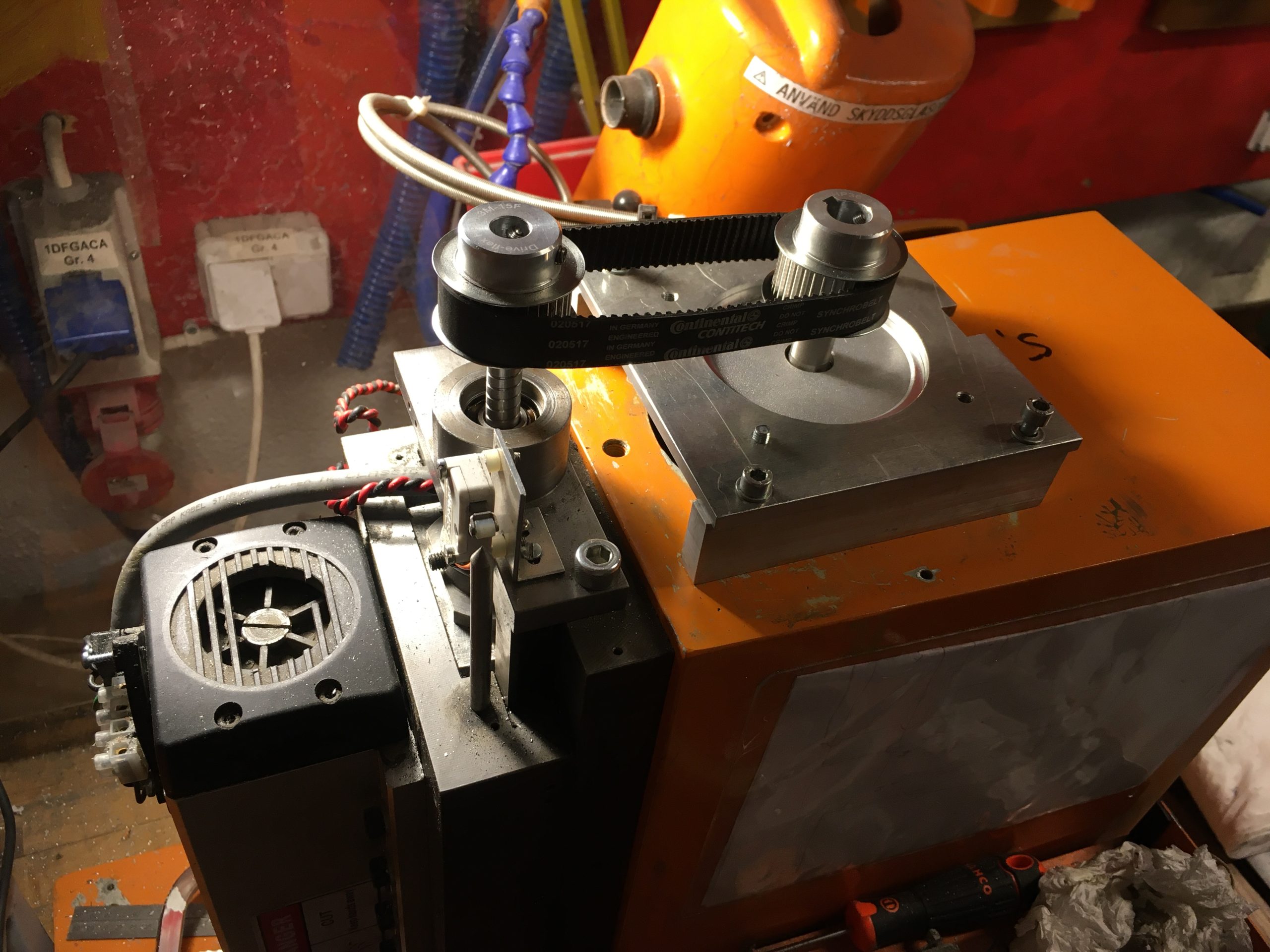

Then I noticed that the mister wasn’t working. So I had to take it apart. It seems that the O-ring does not grip the inner tube properly, meaning pressure air leaks into the space where the alcohol should run. Forcing the tube to become a little wider by forcing a 2.5mm drill bit into it seemed to do the trick. Now it sprays a fine and stable mist.

So mister was fixed. Time to see if the glue method really worked…..

Worked like a charm! Part came out just the way I was hoping for.

Lessons learned:

- CNC-ing is an expensive hobby. Jogged a 4mm end-mill straight off while touching off. Great start…… fortunately, I had a spare.

- Assuming that the top of the spoil-piece will be perfectly square with the machine once you mount it is a bit naive, give the types of equipment I am working with here. Next time I will place the spoilpiece in the machine, polish off the top to ensure it is flat and square, then glue the stock while the spoil piece is in place in the machine.

- Using tabs was a great idea. With the super-glue method, surface area is everything. By using a contour with tabs to finish off any pockets that go all the way through, any pocket large enough will get a piece in the middle that helps keep the part down.

- Getting tape-glue into the end-mill is probably a really bad thing, so next time, I will add a second layer of masking tape to n open space on the spoil-piece and touch off my z against that. This should mean that the end-mill will not mill into any of the actual tape. Worst-case scenario, the end-mitt doesn’t go all the way down through the metal, but the remaining piece will be so thin it does not matter. I can cut it with a knife, even. I will still have to file down the tabs anyways.