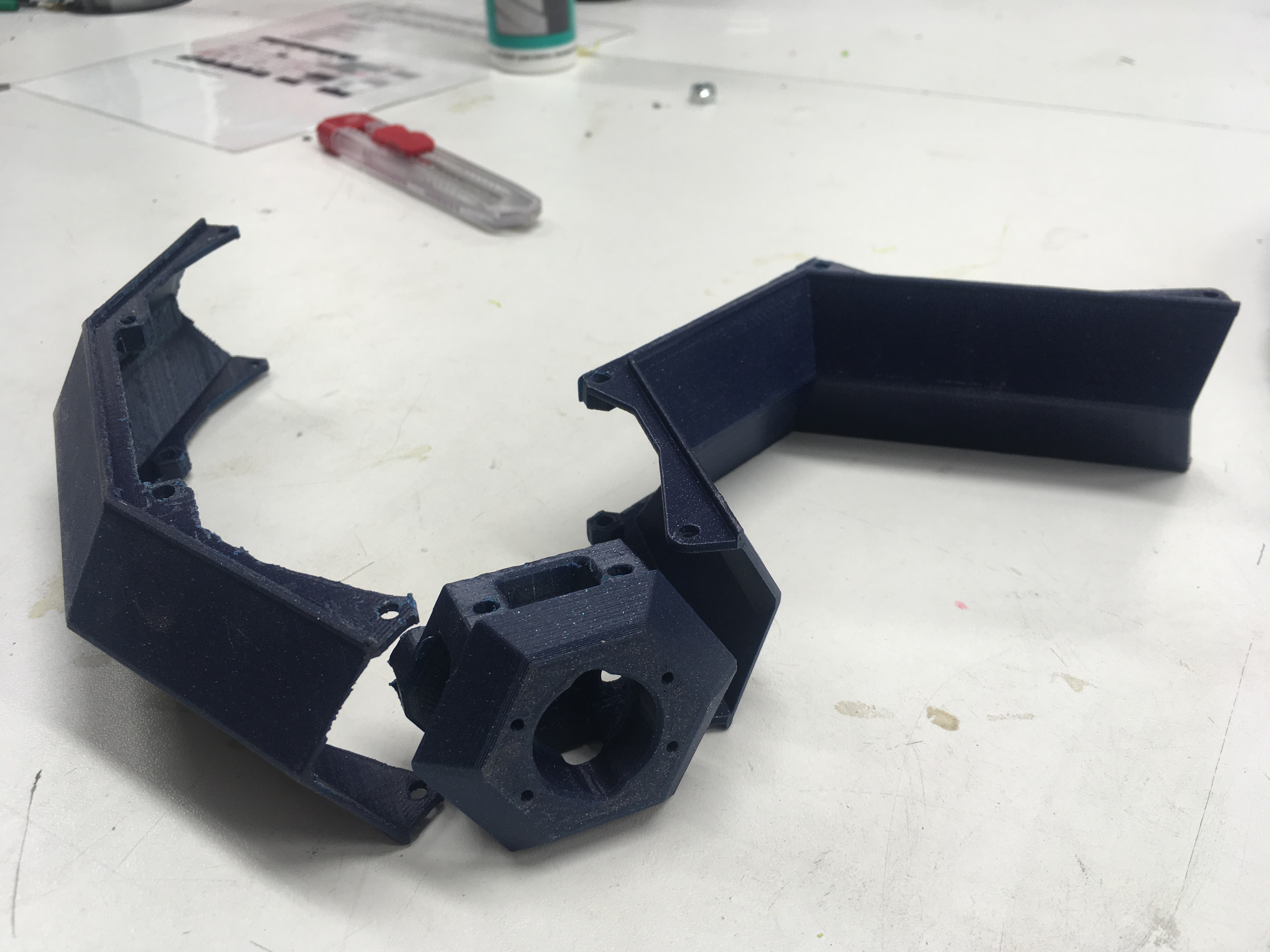

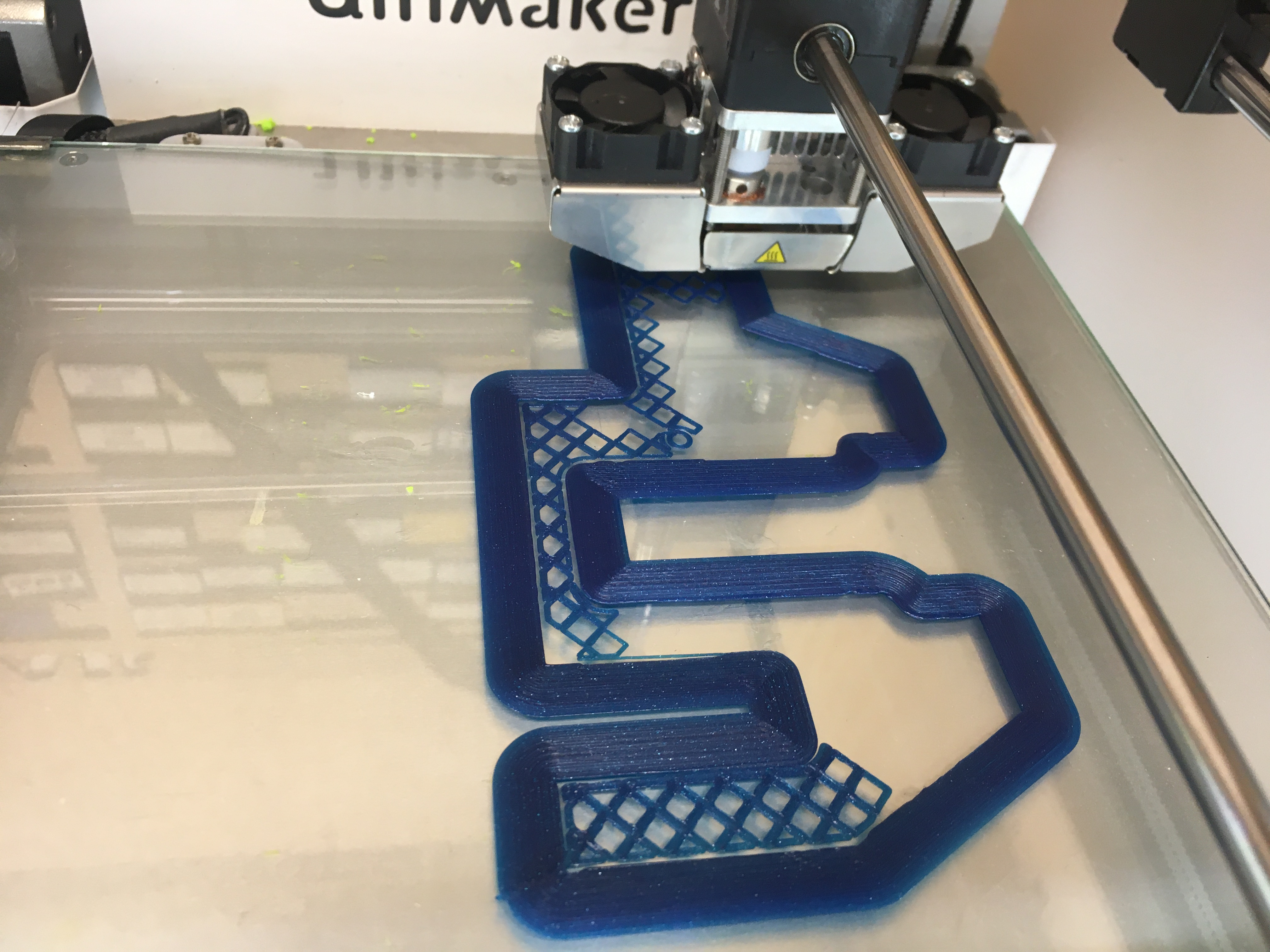

So it seems that the 3D printer consistently prints about 0.1mm thicker than the design.

Oh well, a bit of carving and some adjustments to the model for the next print and it should be fine.

My crafting diary

So it seems that the 3D printer consistently prints about 0.1mm thicker than the design.

Oh well, a bit of carving and some adjustments to the model for the next print and it should be fine.

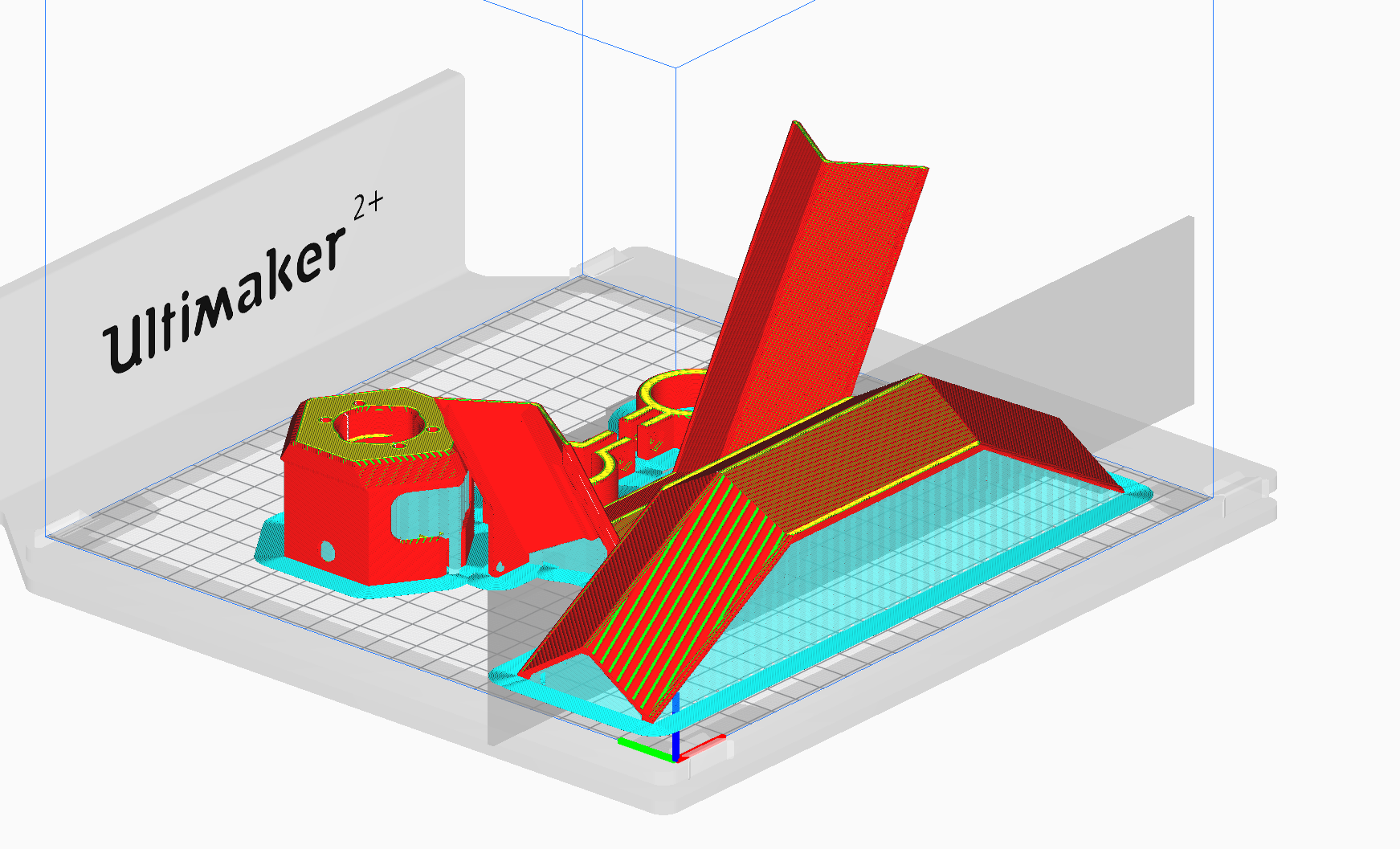

So today I picked up the pieces. Lots and lots of support, yes. But after some effort, all of the support was gone.

While I cleaned up the support, I made a simple mock of the center plate, just to get a feel for it. I went with a mesh patterns to reduce the ammount of material and time. But for some reason, Cura thought it should do each square invidivually rather than do an infill-stype cross pattern. But the print still took only 50 minutes.

Finally, after adding the threaded inserts (What a joy! So easy!) I could screw the entire side together. Does this look professional or what?

So back to the Makerspace for the first time in a while. The plan was to start a print of the mechanical parts and possibly experiment a bit with CNCing in plywood.

The 3D print looks like it is off to a good start. I could only find a 0.6mm nozzle that wasn’t broken but that is close enough.

As for the CNCing it seems that the router is still not done. Oh well, looks like I will have something to do this summer. 😀

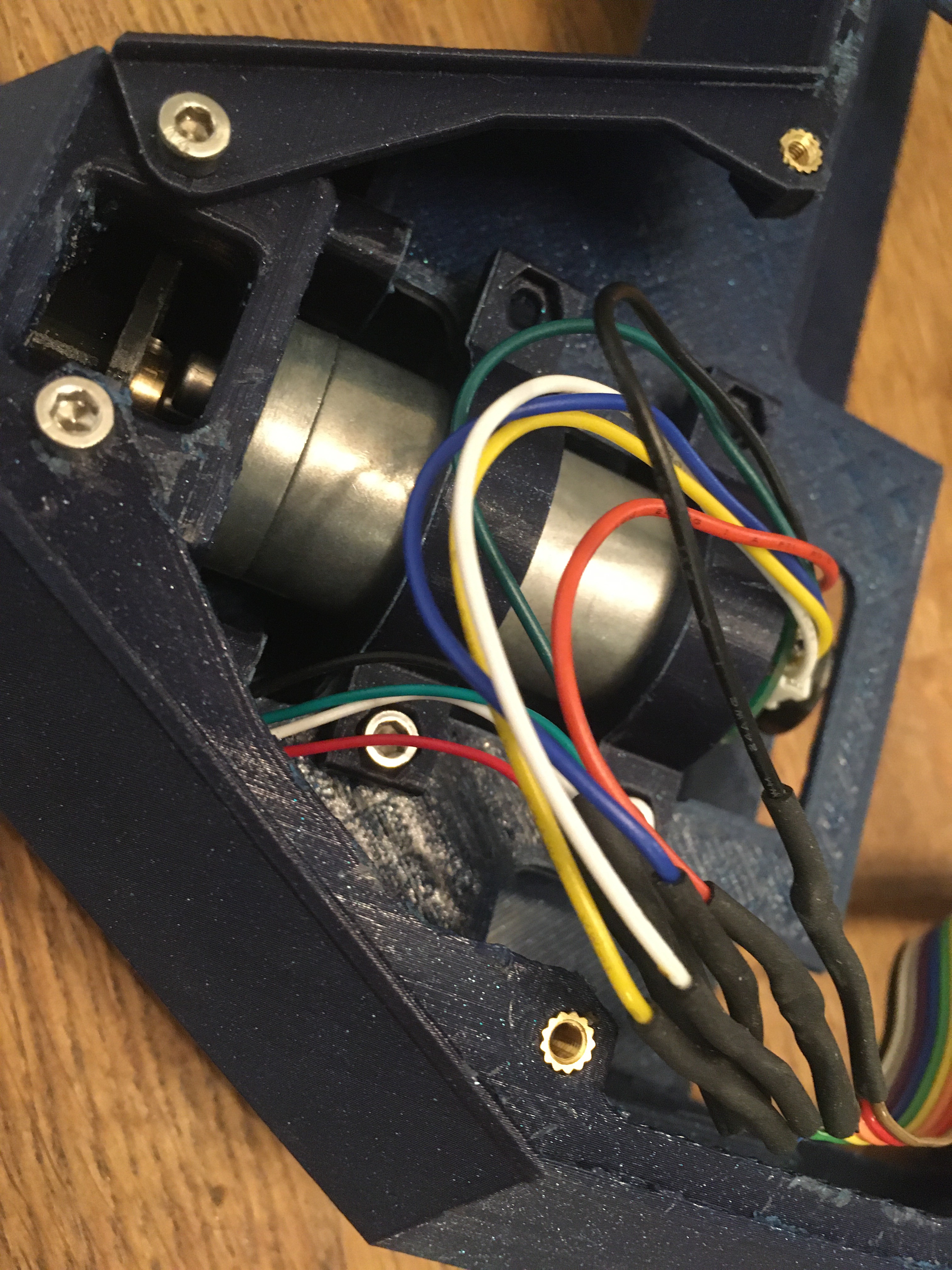

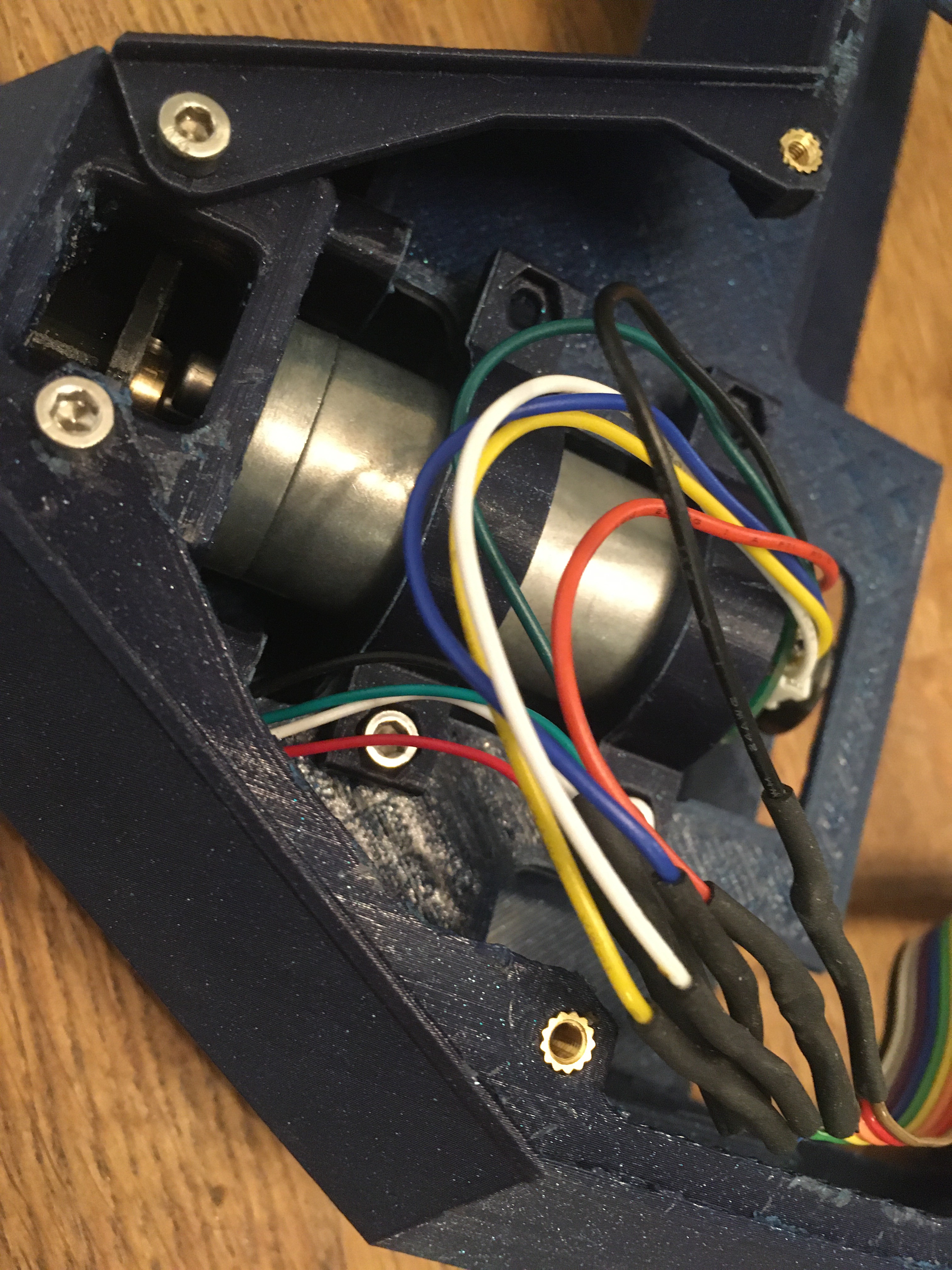

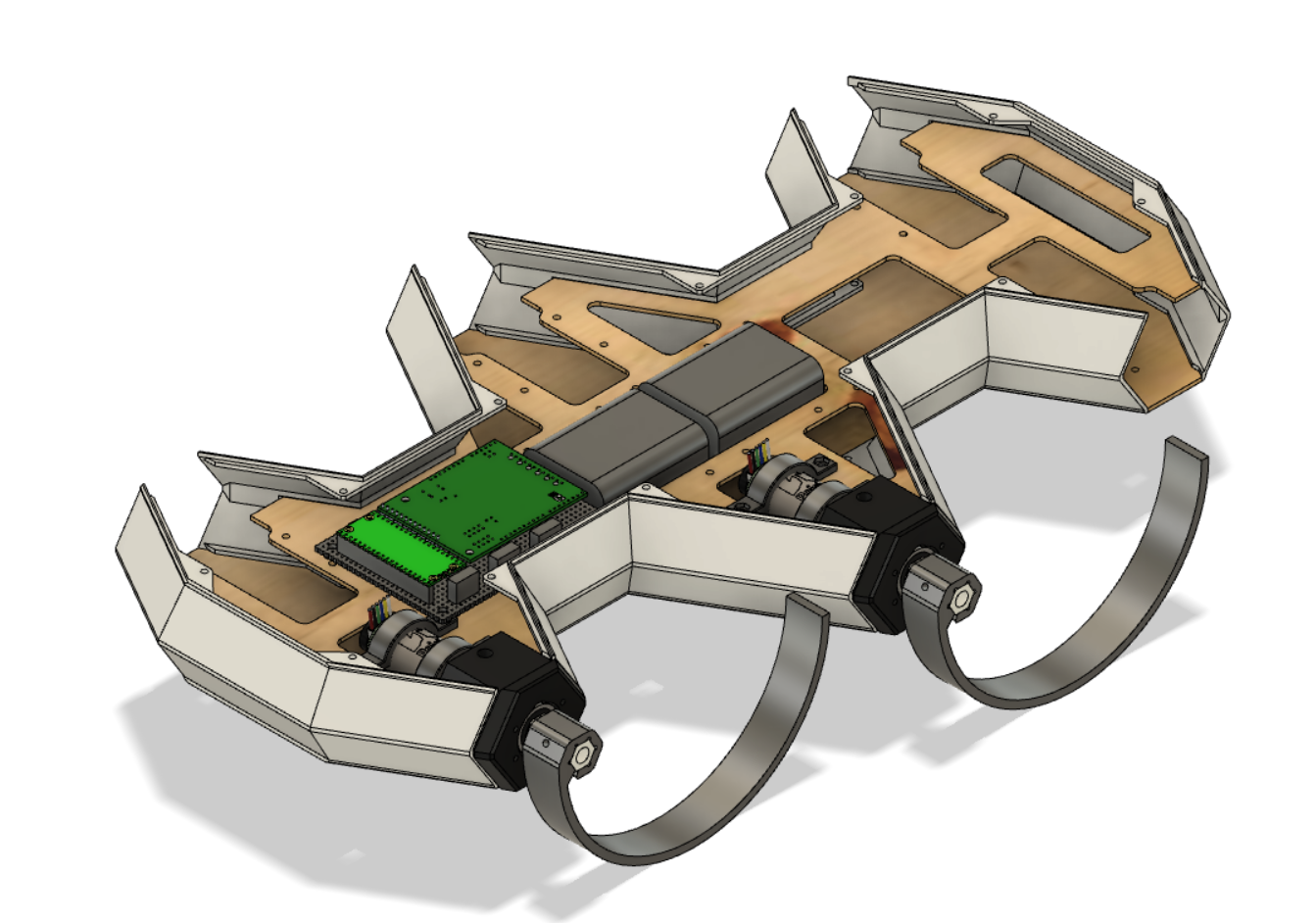

So a bit of experimentation with the modular motor controller gave some very promising results. So I have now orderd all of the material and hopefully I can now rebuild the model using the new and improved designs.

And here we have the 3d-printed parts all set up in Cura

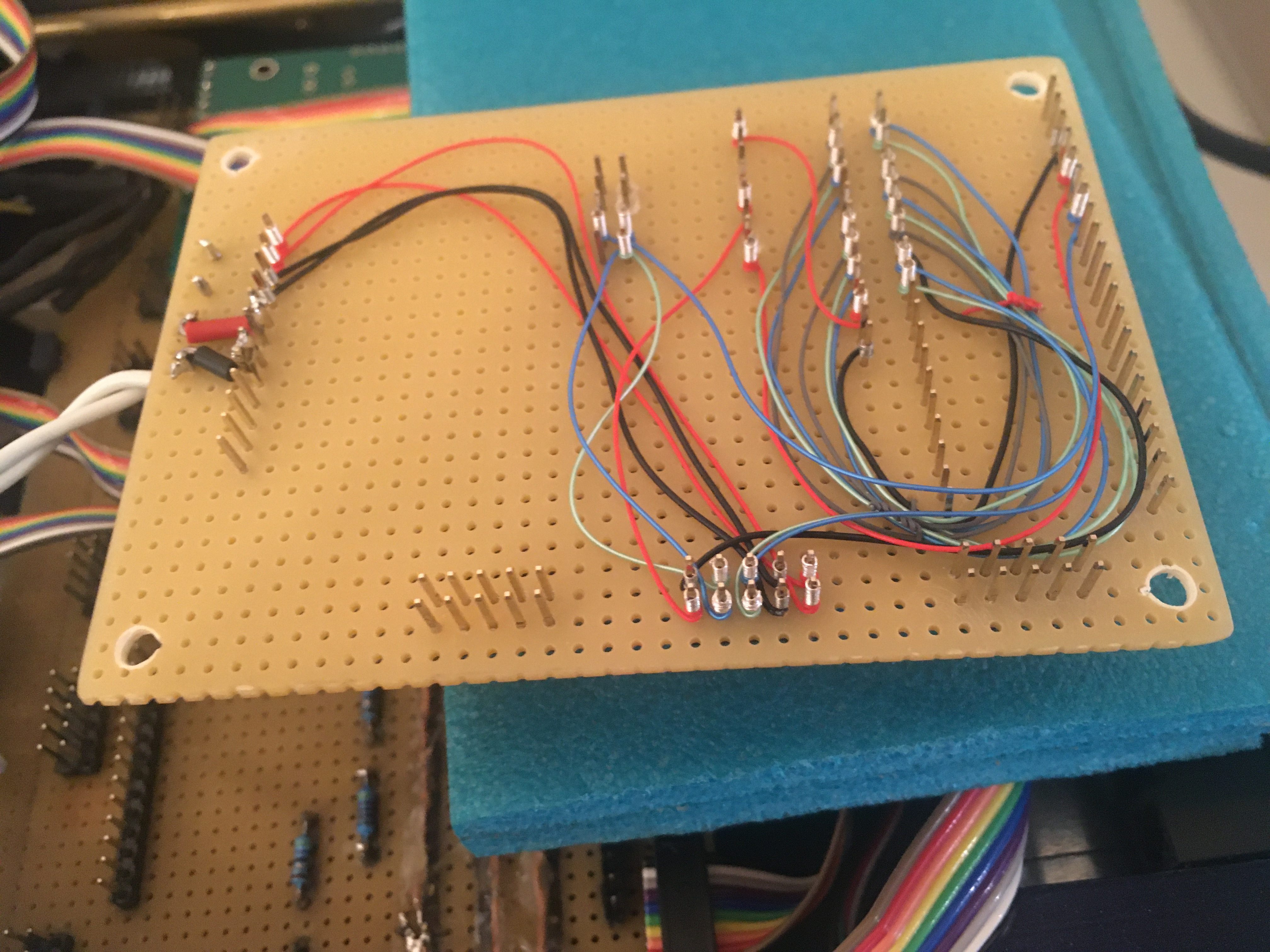

Oh, and here is the motor driver module with all the cables for one motor.Way cleaner than the old design. Also, The Raspberry Pi Pico is a joy to work with. Sure, it is cheating to have that much Power and RAM, but it really does make the programming a breeze. I mean, just the fact that you have dynamic memory….. 😀