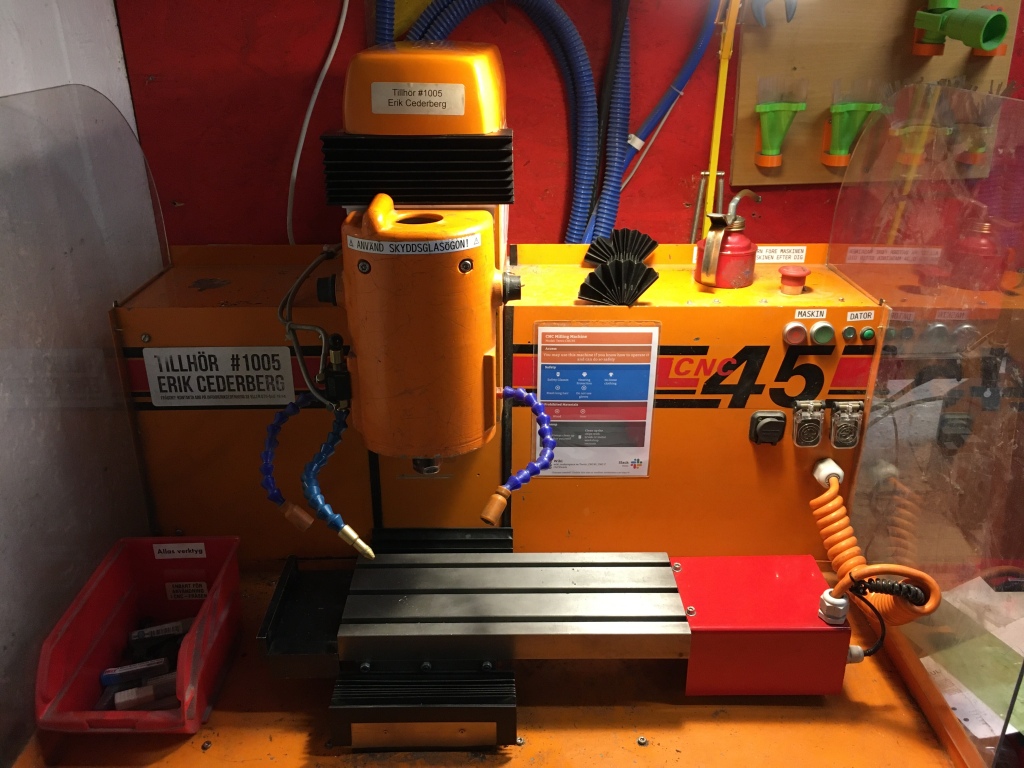

So done I am and the Terco is ready for work. Kudos to Scott who helped me on the home stretch with the X motor box and the Z bellows.

Here it is. 😀

To make sure we get the most out of the new motors, I trimmed them as well. Six times higher max speed and significantly higher acceleration will really cut down on the milling times.

But then, who does 3 axis CNC these days? When we have an A axis just lying around. Some alignment later and we have that squared up as well. 😀

Not only did I get the machine up and running including the A axis. I also machined the firs part on it.

This is a small collet to fasten the leg joints I will be making as I will need to mill right up to the joint fastener and I need some space so I don’t cut into the jaws.