So this week I had scheduled a serious push to really make some progress and I have been to the space every day of the week so far. Yesterday, unfortunately, I got a bit of a cold, so it looks like I will have to cut things short and work from home tomorrow. But I think I have all of the pieces that I needed from there, anyways.

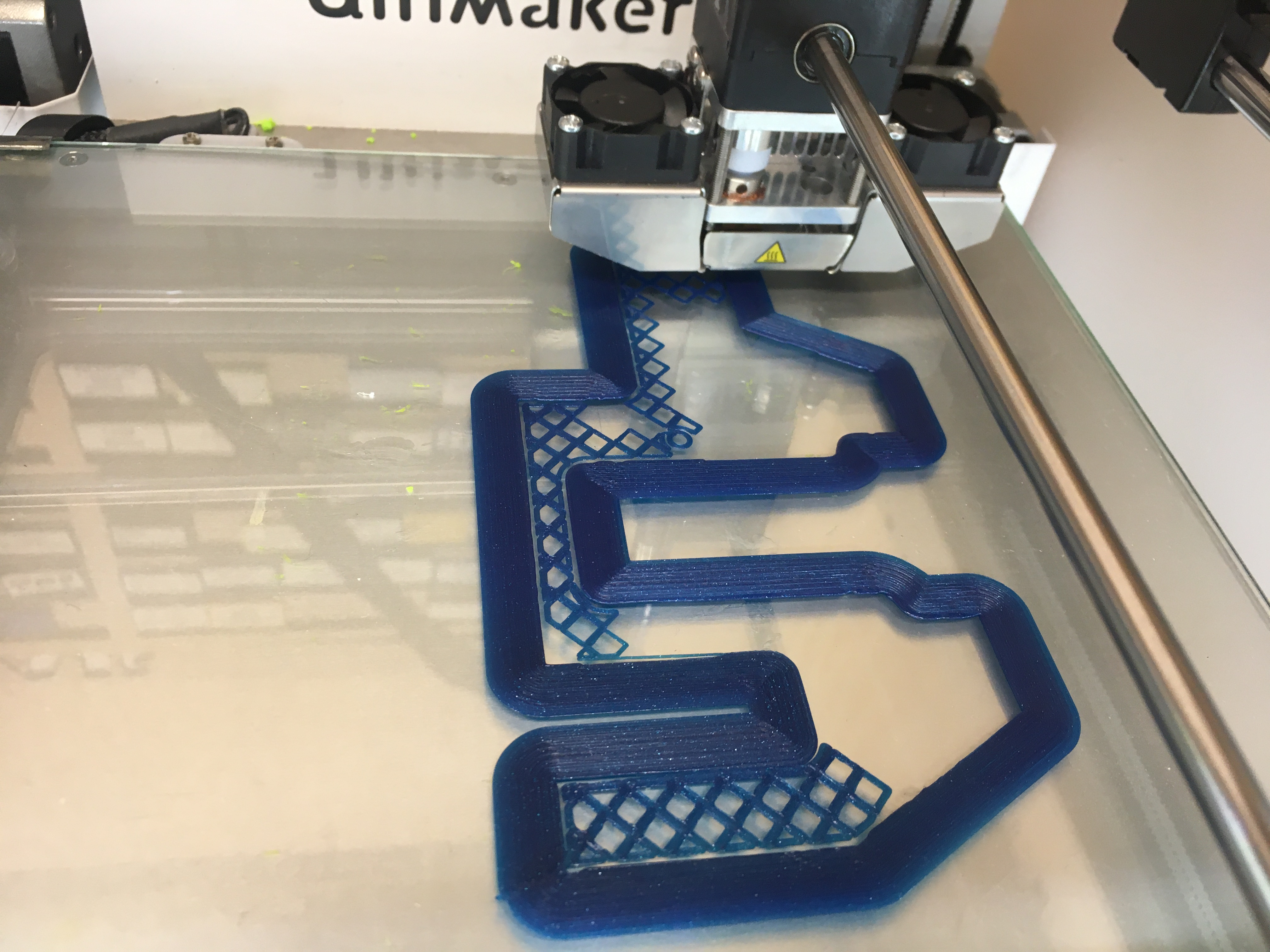

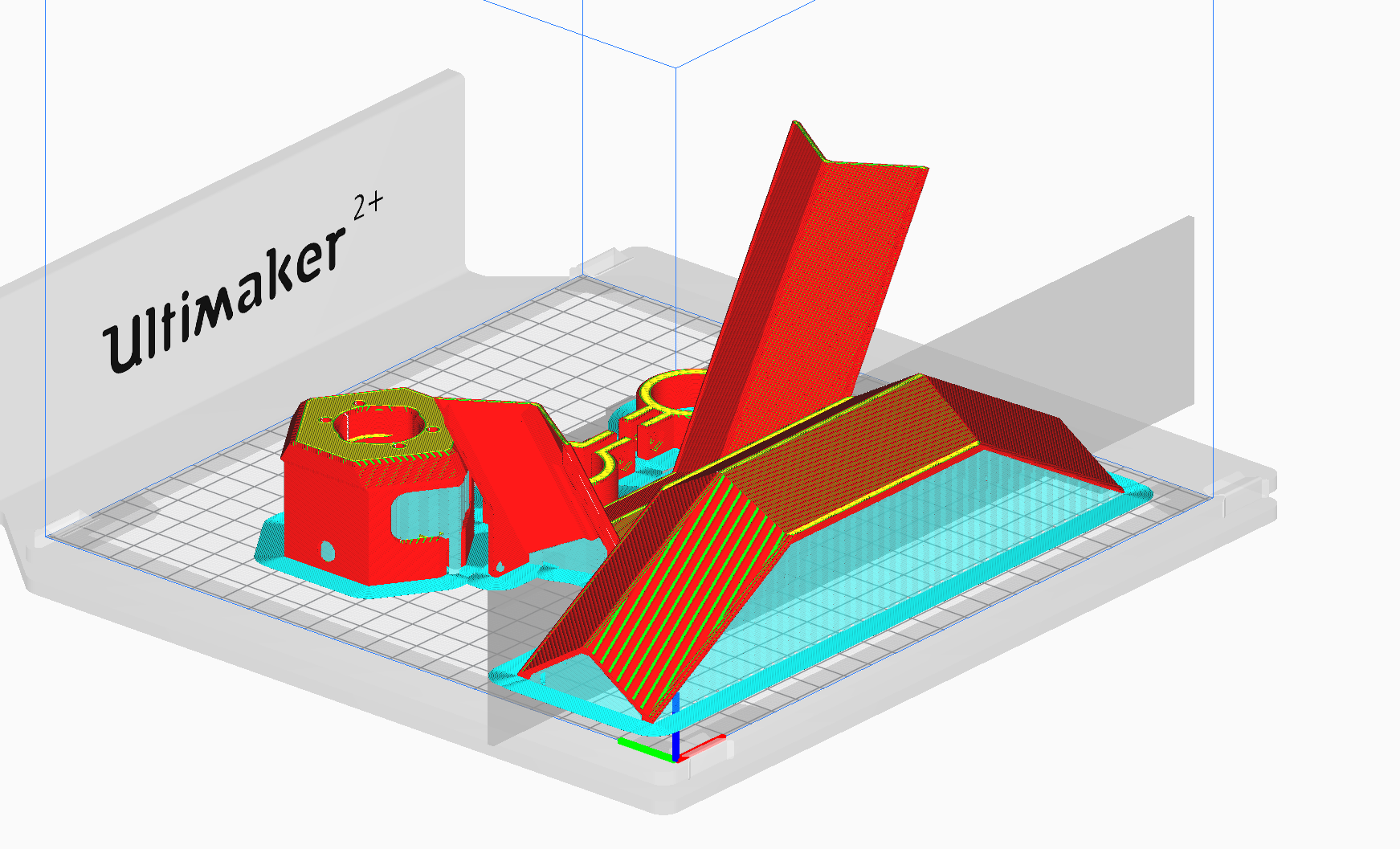

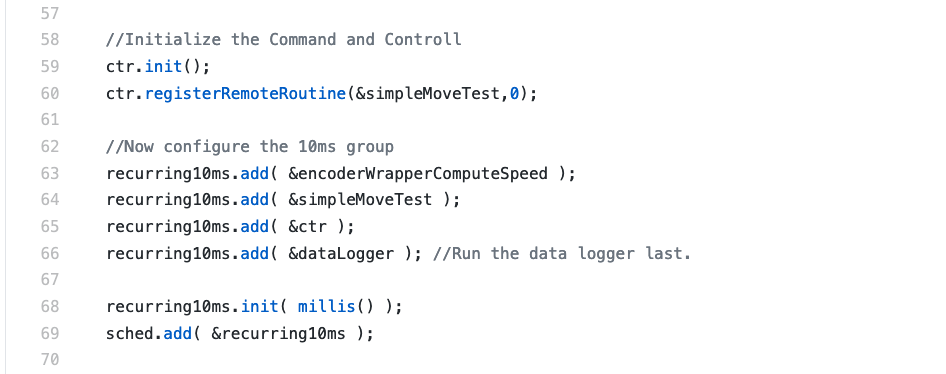

The first success of the week was when I, after a few failed attempts that were all my fault for not ensuring there was proper support, managed to dial in how to print the front cover. As you can see in the image, the only supports were along the purely flat edges. All the rest worked as simple overhangs (They are about 70 degrees). I finally had to draw a super-detailed support blocker which completely determined where there was to be support and where there was not to be support. But once I admitted that this had to be done, the results were spectacular.

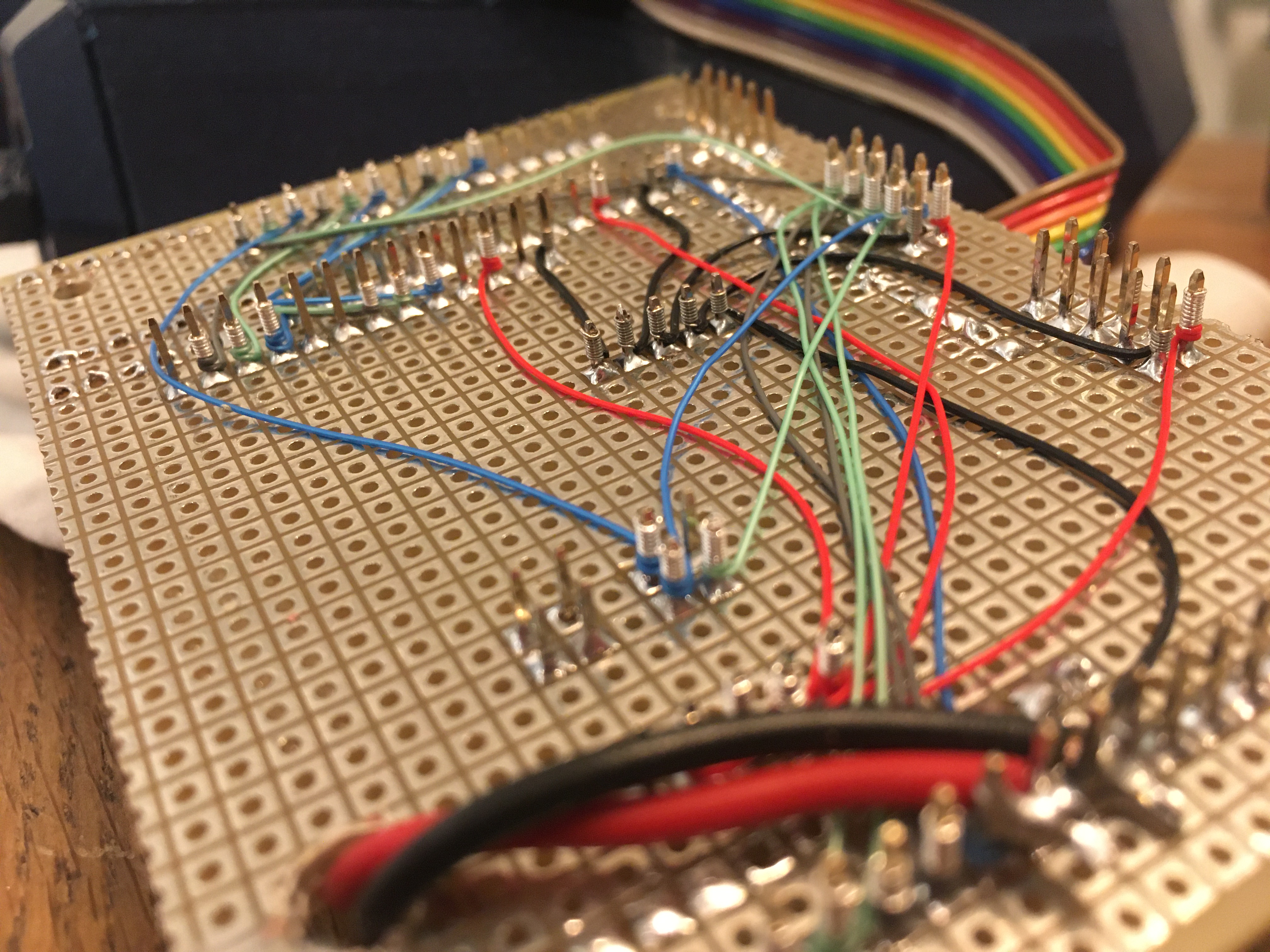

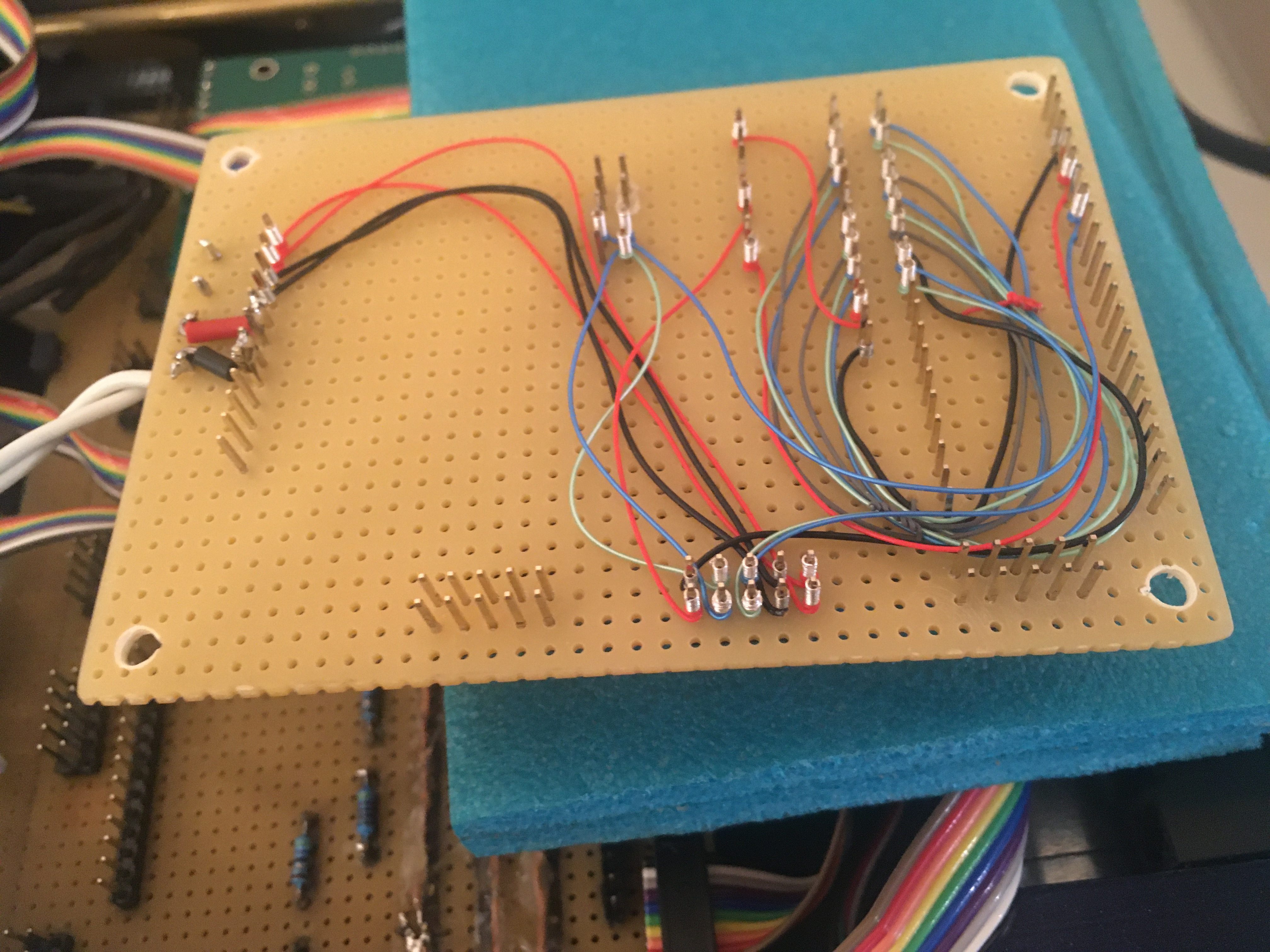

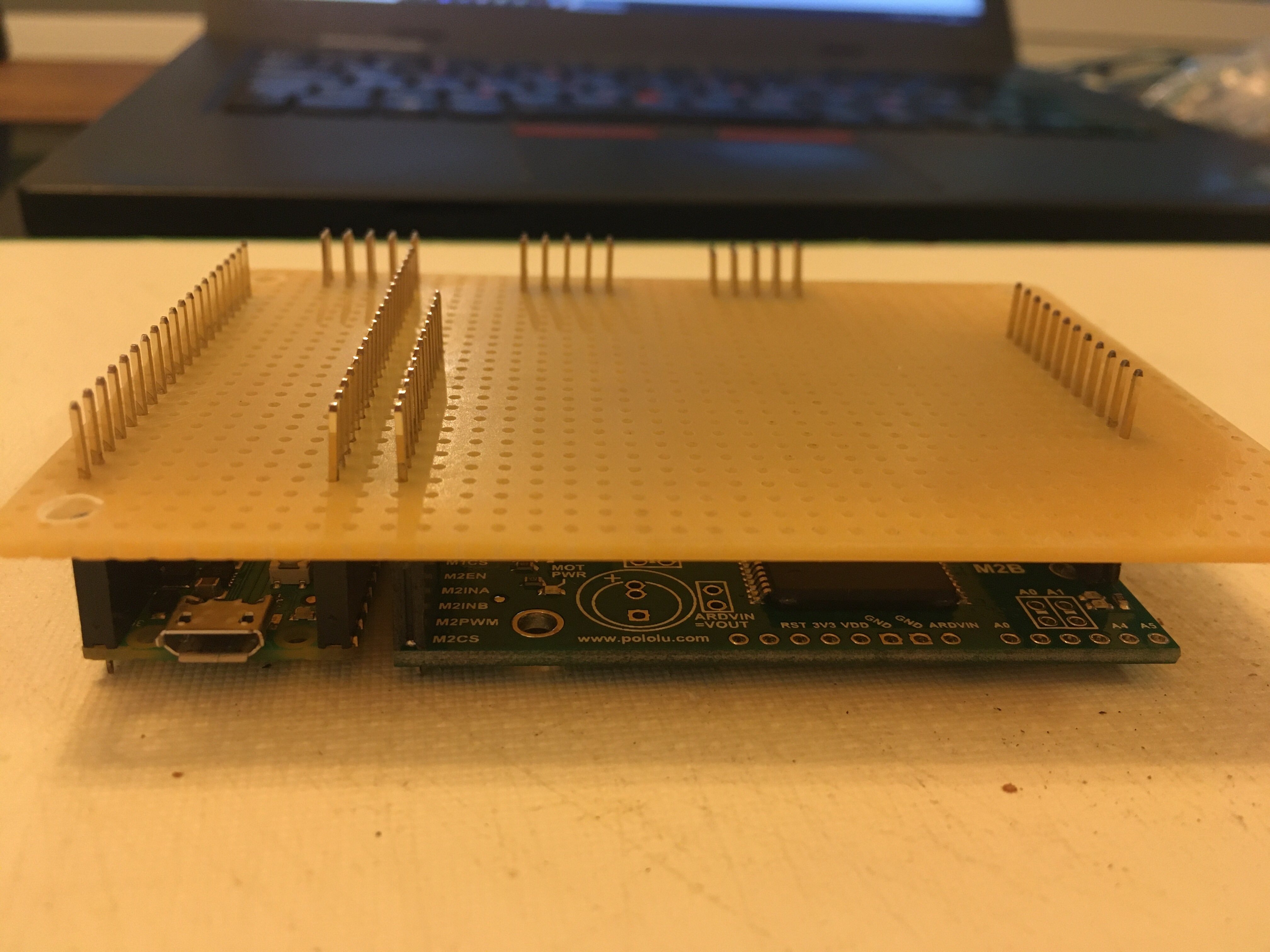

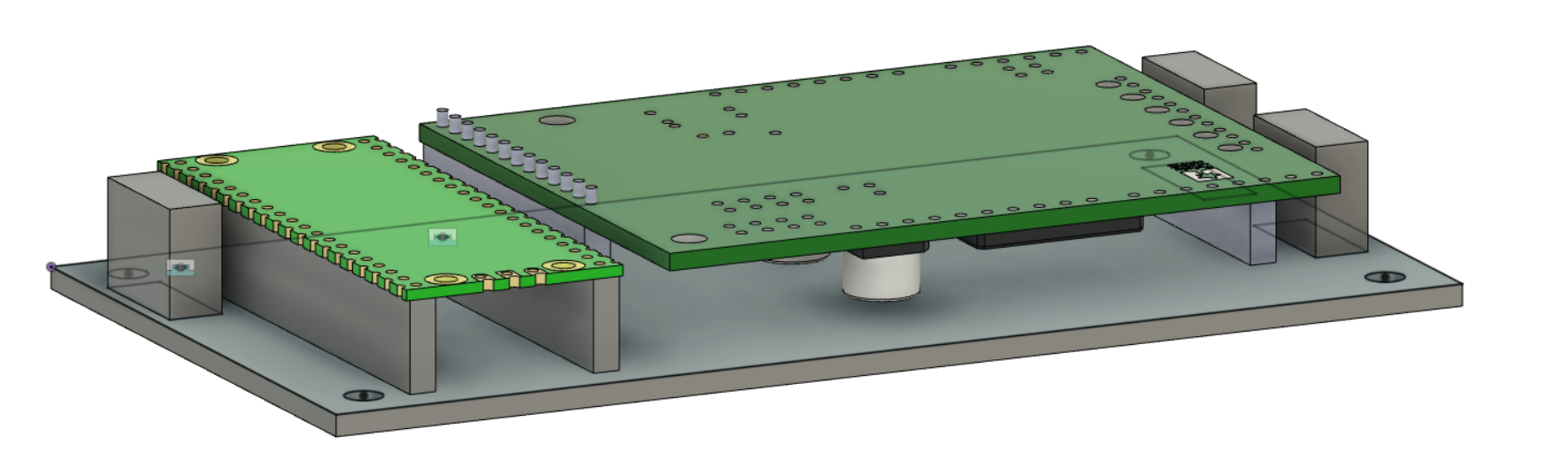

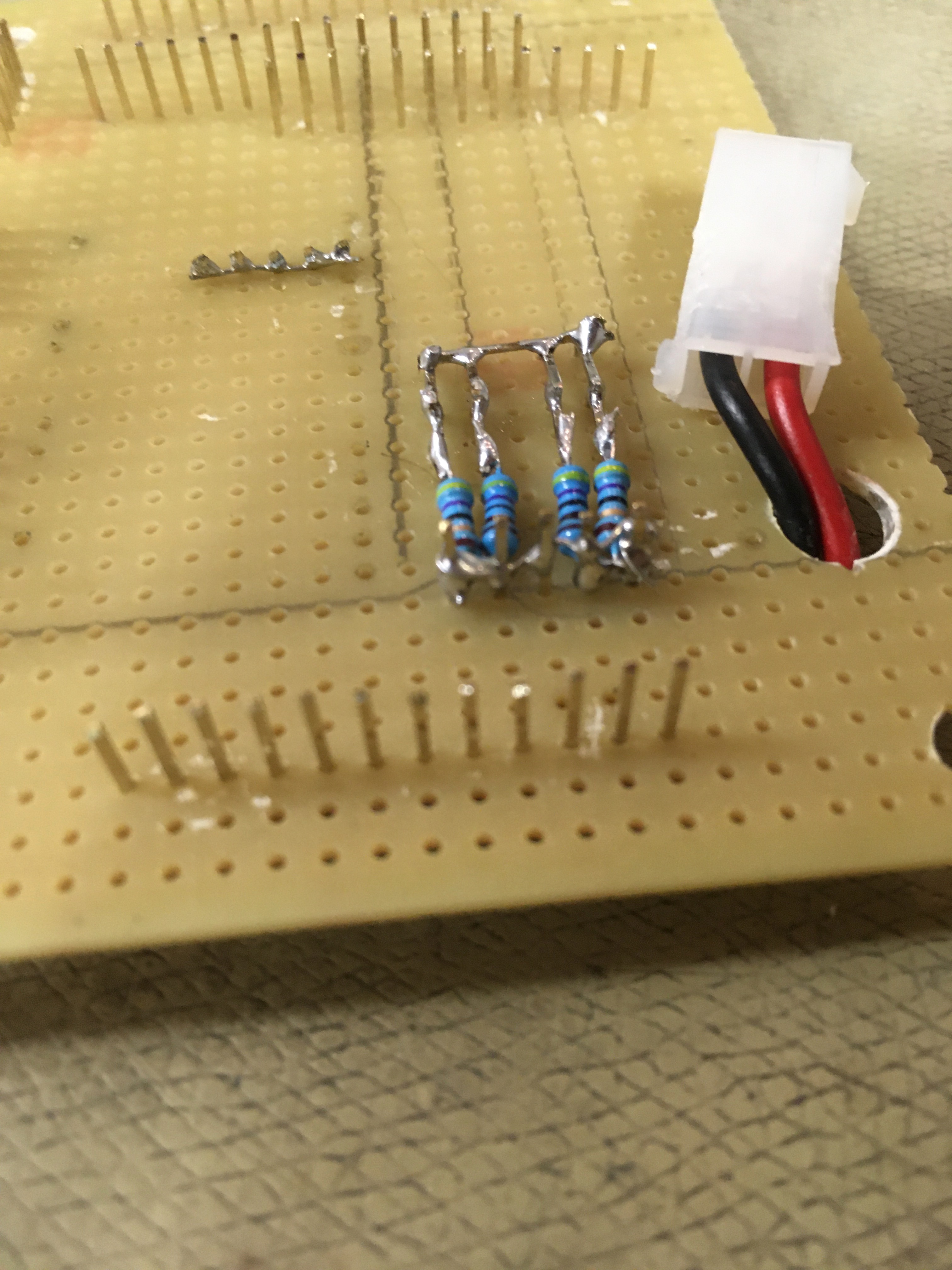

The next big thing I did was create two more driver boards. After having miscounted a pin on the first one which led to the motor not running at all, the rest went almost without issue. Here is a work-in-progress image of one of the driver boards. Can you spot the stupid error on this one?

If you look closely, you can see that the small bank of 4 resistors are wired together on both ends. Yeah, sometimes you wire resistors in parallel, but this was not a case like that. That was a lesson in allways controll-measuring your connectors before running them. Fortunately, there was no damage.

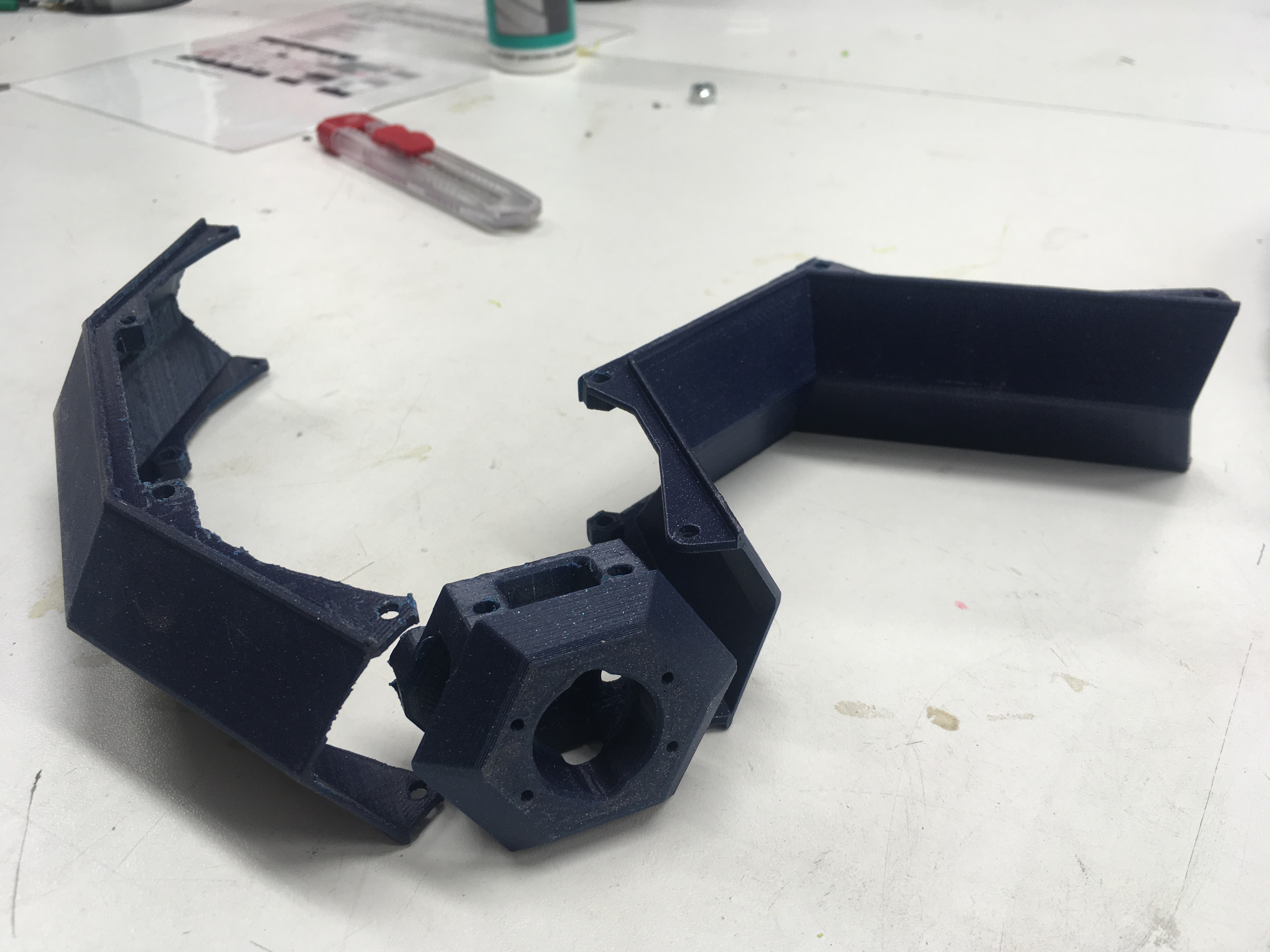

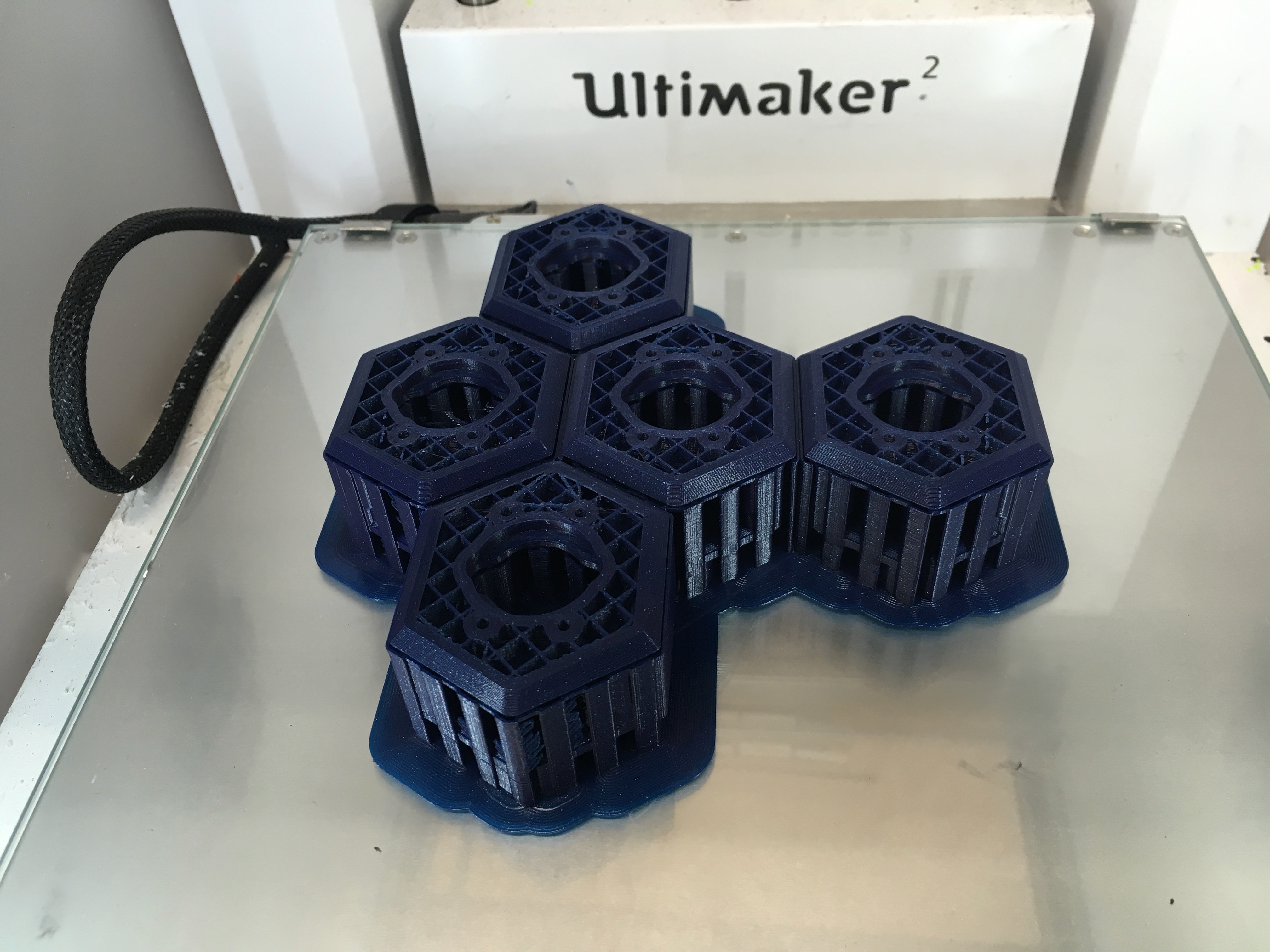

A third major component that was missing was the additional covers and leg join chassis. The covers printed perfectly the first time. The leg joints, though. There are pretty solid and rather complex, so they take forever to print. First two Bowden tubes fell out which stopped the prints. Then some really wierd issue happened, twice, where the printer simply fed back the filament and then continued printing as if all was fine. The theory is that the SD card was getting a bit old.

Here you see the last half-completed print. It is something like 90% done. Forunately, Erifor helped me out and showed me how to restart the print, and he tells me that the final pieces are now successfully printed. Will pick them up tomorrow.

Oh, and he cut out another cover with the laser for me, so I owe him twice.

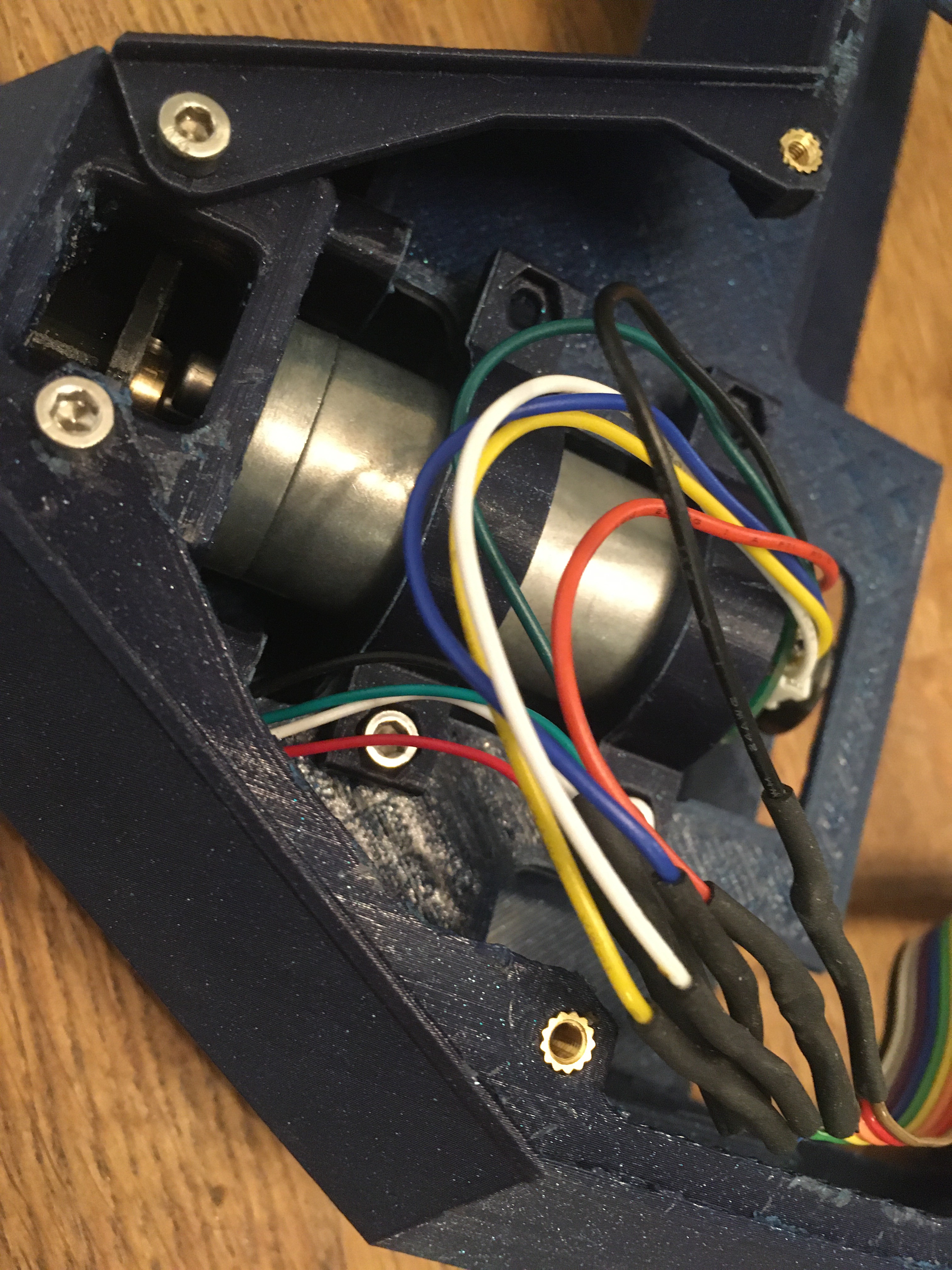

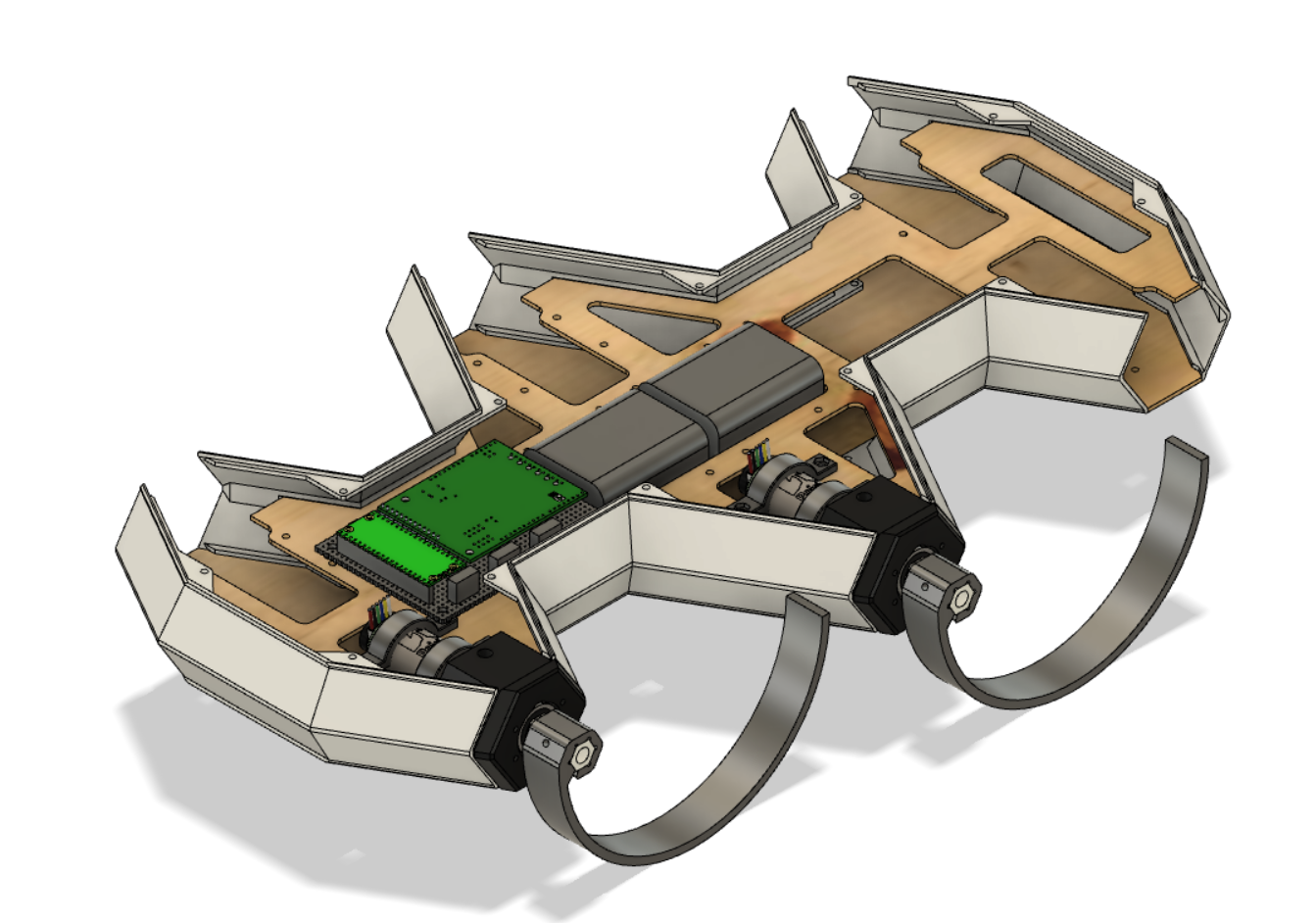

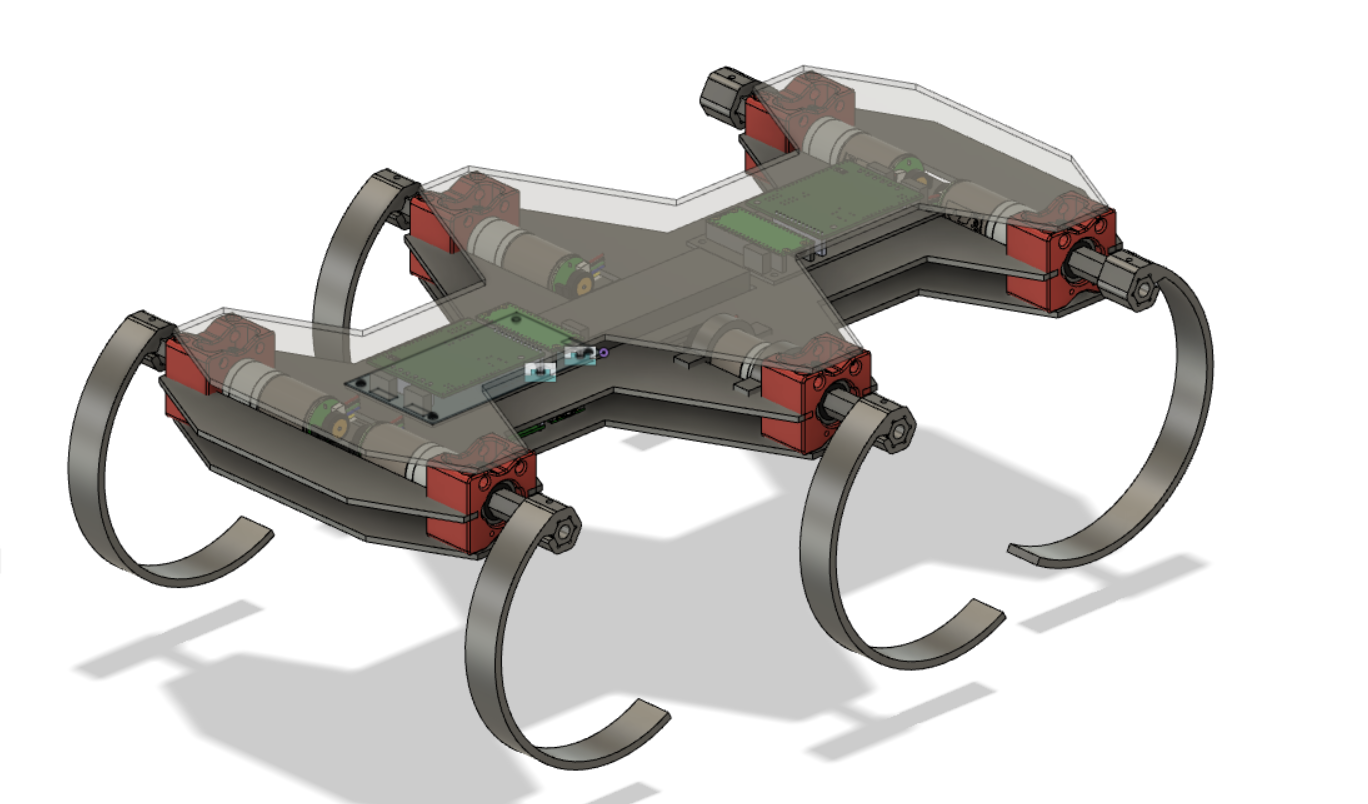

With that, I could assemble the whole thing. You can for example see the pins that I drew and printed to attach the driver cards. I will replace those with long screws, but I didn’t have any.

Also, you can see the power cabling if you look carefully. If I connect all three driver boards, then they reset right after start, so I think I will need a more powerful power adapter. I will have to measure the voltage drop as I power the machine and see if that is the real issue here. But for now I can still power up with two driver boards and that is enough.

Oh, and I also created the inlays for the case. No picture of that right now, so that will have to come next time, if I remember.