Today I focused mostly on improving things at the makerspace.

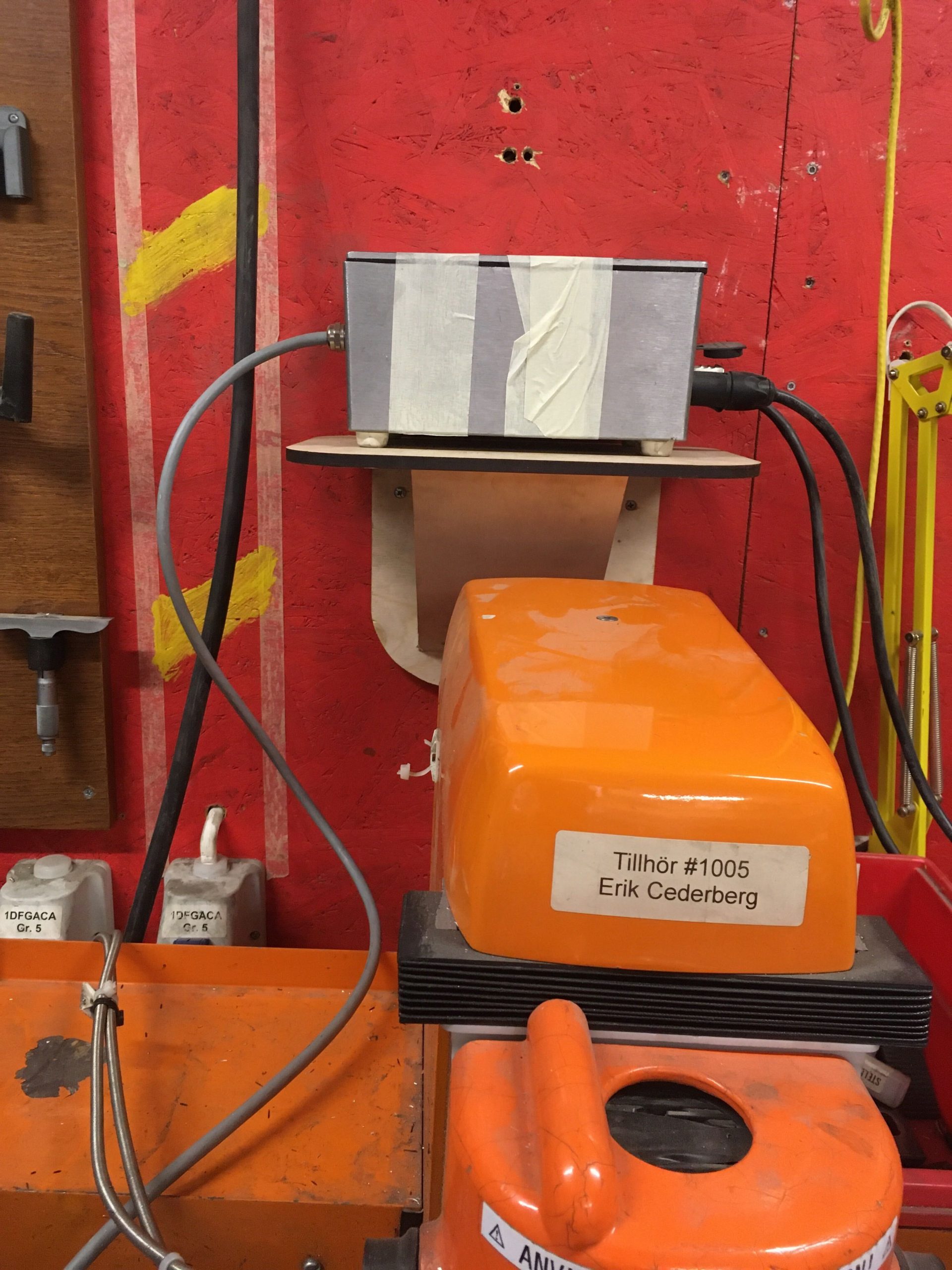

Short and friendly signs on the planar and the doors. Better instructions and some helpful arrows on the chip evacuator. And a shelf for the fourth axixs driver for the Terco. That last one was one of the uglyest things I have made in a long time, but for about 10 minutes of work and the joy of using a nail gun for the first time I am fairly pleased.

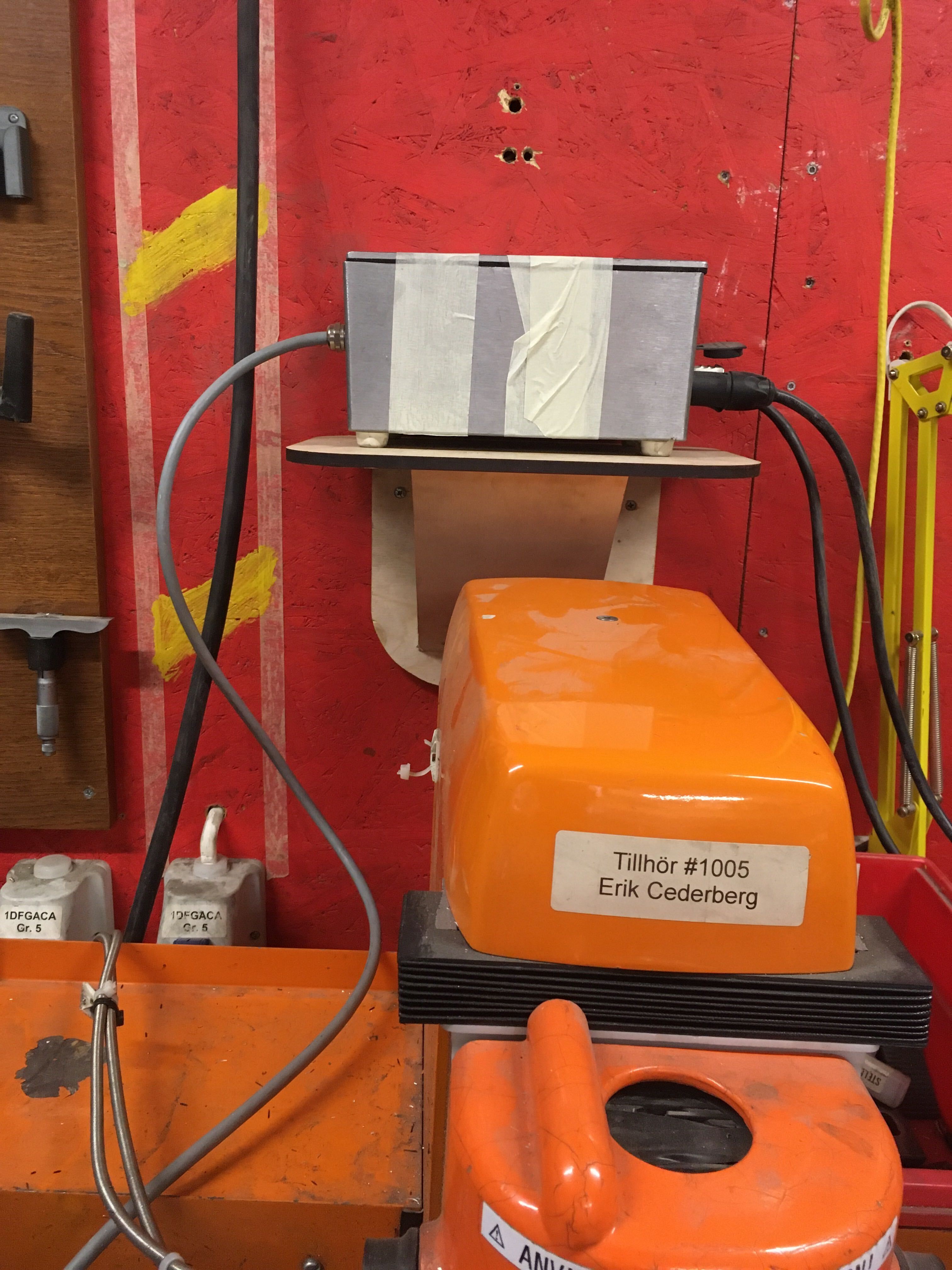

Also, I started performing the load testing on the 3d printed parts that Eric had made from different materials. Enthusiastically, I started with the PLA in the belief that I could break it….. Turns out that it doesn’t even grumbe under 20 kgs. The box you see below weight in at much more than 20kgs, probably something like 30kgs but the scale did not go that high.

Yeah, you can hardly see the part being tested in the picture. It is the small black cube in the middle. Surface area at the weakest point is less than 2cm2.

At this point, I decided that continuing would be irresponsible, so I ended the test there and then. In order to continue, I would need a newton meter that can handle at least 1000N, and probably 10 times as much.

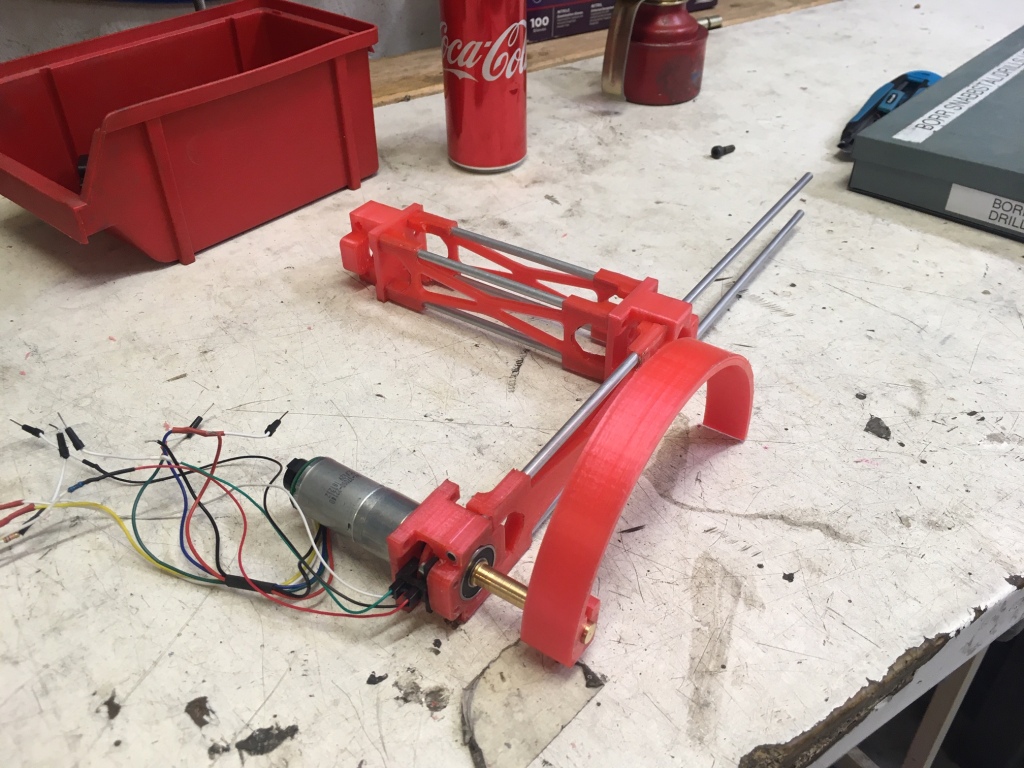

Finally, I did do some polish to the rHex parts and mounted them together so see how they fit. Turns out there is some room for improvement, but in general it is really starting to look like something.