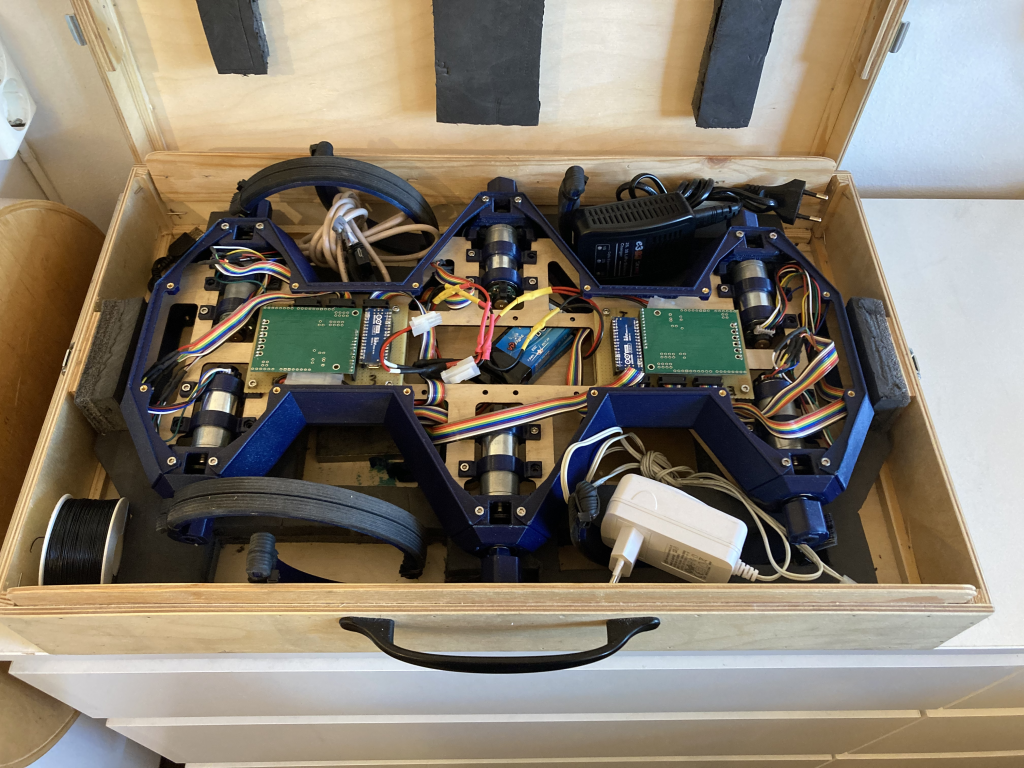

So as we will be moving to Bangalore for a year, and I cannot bring an entire electro-mechanics lab with me, I had a pretty hard deadline to wrap up the hex project one way or another.

So I set myself the goal that I wanted to capture a film of the thing walking. That meant that all of the components had to actually be in place and working together. It took one full day of work, but here it is!

So yeah, it looks like a drunk dog trying to get home after having been hit by a car….. So not that impressive. But I am still super-happy because I have learned so very much, and I am still super-pleased with the visual design of the robot.

Lessons

First some super-specific things I learned:

- CNC-milling in aluminium is HARD! Especially without a tool changer and on an old machine with only a weak mister for chip evacuation.

- FDM 3d-printing with PLA combined with threaded inserts is awesomely simple and practical.

- Wire wrapping is also totally practical for prototype boards.

- Test driven development is the only way to fly in software. Especially on an embedded platform without a debugger.

- Cogging Torque was a thing I had never heard of, but it is the thing stopping this robot from not looking like it has nerve damage. So always check that when buying a motor.

But seriously

To take a slightly more serious spin, here is a summary of the project in terms of what it cost me and what I gained.

- I have spent at least 4 hours per week for three years on this project, and probably more. So at least 750 hours in total.

- I have spent at least 20 000kr just for parts.

I have had to make use of the following skills:

- Dynamics simulation in Matlab

- CAD-design in Fusion 360

- Stress analysis and torque stability simulations

- CNC milling

- CNC machine service including replacing the drive screws and motors.

- Planning order of operations in assembly

- FDM 3d-printing

- Laser cutting

- Plywood and nail gun rapid construction

- Wire wrapping and soldering

- Electronic signal analysis

- Low-level programming

- Test-Driven Development

- I2C communications

What would I change next time?

Not much in terms of process. Of course I know more now and would avoid a lot of dead ends, but I have no regrets. But there are some parts of the robot that should be changed if I ever pick up this project again and have lots of money.

- New large-diameter motors with minimal cogging torque so I can move precisely at slow speeds.

- Better power connectors as these jammed a lot.

- Connecting the driver boards with USB so they can all be reprogrammed in a CI/CD workflow.

Farewell

So with that, it is time to say goodbye to the Hex for now. We had a good run, you and I. I will miss you. 🥰 😢